I-VPSA PSA vacuum analytical oxygen plant

VPSA PSA vacuum uhlalutyo lwezixhobo zokuvelisa ioksijini

Uhlobo lwe-VPSA lwe-PSA uhlalutyo lwezixhobo zokuvelisa i-oksijini luthatha i-PSA kunye nohlalutyo lwe-vacuum njengomgaqo, isebenzisa umgangatho ophezulu we-calcium / i-lithium ye-molecular sieve njenge-adsorbent, kwaye ifumana ngokuthe ngqo i-oksijini emoyeni.

EzobugcisaIabafundisi

Isikali semveliso: 100-10000n ㎥ / h

Ukucoceka kweoksijini: ≥ 70-94%

Uxinzelelo lweoksijini: ≤ 20KPa (ixabiso eliphezulu kakhulu)

Izinga lokusebenza ngonyaka: ≥ 95%

Wumgaqo wokusebenza

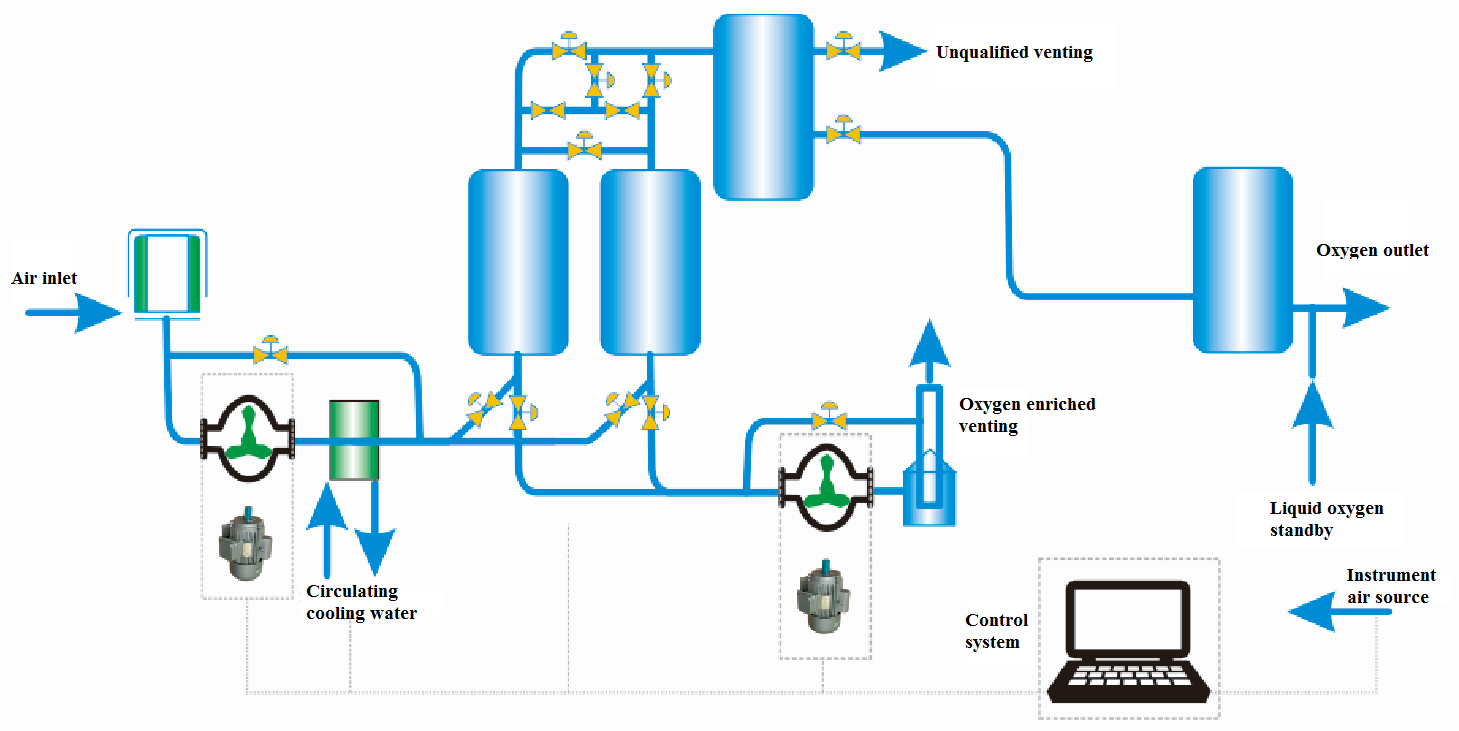

Isixhobo sokuvelisa i-VPSA vacuum desorption i-oksijini ikakhulu yenziwe nge-blower, i-vacuum pump, i-valve yokutshintsha, i-adsorber kunye ne-oxygen balance tank.Umoya okrwada ucinezelwa ziingcambu zokuvuthela kwi-adsorber egcwele i-oxygen molecular sieve, apho amanzi, i-carbon dioxide kunye ne-nitrogen zibhengezwa khona ukuvelisa i-oksijini.Xa i-adsorption ifikelela kwinqanaba elithile, i-vacuum pump isetyenziselwa ukucoca amanzi adsorbed, i-carbon dioxide, i-nitrogen kunye nenani elincinane lamanye amaqela egesi ngokulandelelanayo akhutshwe kwaye akhutshwe emoyeni, kwaye i-adsorbent ihlaziywa.La manyathelo enkqubo angentla alawulwa ngokuzenzekelayo yi-PLC kunye nenkqubo yevalve yokutshintsha.

Itshati yokuqukuqela eyenziwe lula

Isihluzo somoya

Umvutheli

Inkqubo yokulawula ubushushu

Inkqubo ye-Adsorption

Itanki yebhalansi yeoksijini

Impompo yokufunxa

Isithulisi sokuphuma

Itanki yokugcina ioksijini

AisiceloANONE

Ishishini leMetallological:Ukwenziwa kwentsimbi ye-EAF, ukwenza intsimbi yesithando somlilo, ioksijini etyetyisiweyo yesithando somlilo esixhasayo

Ishishini lokunyibilikisa elingeyiyo i-ferrous:ukunyibilikiswa kwelothe, ukunyibilikiswa kobhedu, ukunyibilikiswa kwe-zinc, ukunyibilikiswa kwe-aluminiyam, ukunyibilikiswa kweoksijini kwiziko ezahlukeneyo

Ishishini lokhuseleko lokusingqongileyo:unyango lwamanzi okusela, unyango lwamanzi asetyenzisiweyo, i-pulp bleaching, unyango lwe-biochemical yalindle

Ishishini lemichiza:ezahlukeneyo oxidation reactions, imveliso ozone, amalahle gasification

Ishishini lezonyango:ibha ye-oxygen, unyango lwe-oxygen, ukhathalelo lwempilo yomzimba

Ulimo lwasemanzini:Ulimo lwaselwandle kunye namanzi acocekileyo

Amanye amashishini:ukubiliswa, ukusika, iziko leglasi, umoya womoya, ukutshisa inkunkuma

Intsimi yesicelo kunye nokuthelekisa kunye nendlela ye-cryogenic

Umsebenzi wokuvuthela ioksijini kwiziko elivulekileyo lomlilo kukuxhasa ukutsha.Injongo yalo kukomeleza inkqubo yokunyibilikisa, ukunciphisa ixesha lokunyibilikisa kunye nokwandisa imveliso yentsimbi yesithando somlilo esivulekileyo.Kuye kwangqinwa ukuba ukuvuthela kweoksijini kwiziko elivulekileyo lomlilo kunokunyusa imveliso yentsimbi ngaphezu kwexesha elinye kwaye kunciphise ukusetyenziswa kwamafutha ngama-33% ~ 50%.

Ioksijini esetyenziswa kwiziko lombane inokukhawulezisa ukunyibilika kwentlawulo yesithando somlilo kunye ne-oxidation yokungcola, oku kuthetha ukuba ukuvuthuza kweoksijini kwisithando sombane akunakuphucula kuphela umthamo wokuvelisa kodwa nokuphucula umgangatho okhethekileyo.Ukusetyenziswa kwe-oksijeni ngetoni nganye yensimbi yesithando sombane kuyahluka ngokweentlobo ezahlukeneyo zetsimbi eziza kuncibilika, umzekelo, ukusetyenziswa kwe-oksijini ngetoni ye-carbon structural steel yi-20-25m3, ngelixa i-alloy iron ephezulu i-25-30m3.I-oxygen concentration efunekayo yi-90% ~ 94%.

Ukuqhuma kwesithando somlilo esineoksijini ephuculweyo kunokunciphisa kakhulu i-coking kunye nokwandisa imveliso.Ngokutsho kwezibalo, xa i-oxygen concentration inyuswe nge-1%, i-iron imveliso inokunyuswa nge-4% - 6%, kwaye i-coking ingancitshiswa nge-5% - 6%.Ngokukodwa xa intsimbi esekwe emalahleni yenza iqondo lokutofa kwamanzi lifikelela kwi-300kg, isixa seoksijini esihambelanayo yi-300m3 / intsimbi.

Xa ioksijini ingeniswa kwinkqubo yokunyibilika kwezinyithi ezingenayo i-ferrous, isulfure inokutshiswa ngokupheleleyo, ubushushu obunyibilikayo bunokugcinwa kwaye isantya sokunyibilika sinokunyuswa.Ukuthatha ubhedu njengomzekelo, i-oksijini ephuculweyo ye-copper smelting ingagcina amandla angama-50%, oko kukuthi, phantsi kokusetyenziswa kwamafutha afanayo, ukuveliswa kobhedu kunokuphindwa kabini.

| Udidi lweprojekthi | Isityalo sokwahlula umoya weCryogenic | I-VPSA PSA vacuum analytical oxygen plant |

| Umgaqo wokwahlula | Nciphisa umoya kwaye uwahlule ngokwamanqaku ahlukeneyo abilayo eoksijini kunye ne-ammonia | Uxinzelelo lwe-adsorption, i-vacuum desorption, usebenzisa amandla ahlukeneyo e-adsorption ye-oxygen kunye ne-nitrogen ukuphumeza ukwahlukana. |

| Iimpawu zenkqubo | Ukuhamba kwenkqubo kuntsonkothile, kufuna ukucinezelwa, ukupholisa / ukukhenkceza, ukunyangwa kwangaphambili, ukwandiswa, ukunyibilika, ukwahlulahlula, njl., kwaye ubushushu bokusebenza bungaphantsi kune-180 ℃ | Inkqubo yokuhamba ilula, kuphela uxinzelelo oluphezulu / i-vacuum efunekayo;ubushushu bokusebenza bubushushu obuqhelekileyo |

| Iimpawu eziphambili zesixhobo | Kukho iindawo ezininzi ezihambayo, isakhiwo esiyinkimbinkimbi kunye nesixhobo esixhasayo kunye nezinto zokulawula;icompressor yomoya eyicentrifugal (okanye icompressor engenawoyile yomoya), isahluli samanzi omphunga, isicoci somoya, isitshintshi sobushushu, isandisi sepiston, isahluli sokucoca. | Kukho iindawo ezimbalwa ezihambayo kunye nezinto ezimbalwa zokulawula isixhobo esinye esixhasayo sombhobho wesixhobo.Iblower, i-adsorption tower, impompo yokufunxa, itanki yokugcina ioksijini |

| Iimpawu zokusebenza | Umsebenzi unzima kwaye awukwazi ukuvulwa nangaliphi na ixesha.Ngenxa yokuba iqhutywa phantsi kobushushu obuphantsi kakhulu, phambi kokuba isixhobo sifakwe ekusebenzeni okuqhelekileyo, kufuneka kubekho inkqubo yokupholisa kwangaphambili kunye nokusetyenziswa kwamandla angasebenziyo (ubushushu obuphantsi bokuqokelelwa kolwelo kunye nokufudumeza nokuhlanjululwa).Ixesha elide lokuqalisa kunye nokuvalwa, amaxesha amaninzi, aphezulu iyunithi yokusetyenziswa kwamandla egesi egqityiweyo.Zininzi kwaye zintsonkothileyo ulawulo kunye neendawo zokubeka iliso, ekufuneka zivalwe rhoqo ukuze zigcinwe.Abaqhubi bafuna uqeqesho lwexesha elide lobuchwephesha kunye namava atyebileyo okusebenza. | Kulula ukusebenza, vula njengoko usebenzisa.Ulawulo lokusebenza kunye nokubeka iliso zonke ziqondwa yi-PLC, kunye nokuqaliswa okufutshane kunye nexesha lokucima ngaphantsi kwemizuzu emi-5.Ixesha elingakanani iqula livaliwe ekusebenzeni ngokuqhubekayo akuyi kuchaphazela imeko yokusebenza.Akukho mfuneko yokumisa umatshini ukulungiselela ukulungiswa.Abaqhubi banokusebenza emva koqeqesho lwexeshana elifutshane lobugcisa. |

| Ubungakanani bokusetyenziswa | Ioksijini, iklorini kunye neemveliso ze-hydrogen ziyafuneka;ukucoceka kweoksijini > 99.5% | Ukukhutshwa kwegesi enye, ubunyulu 90-95% |

| Iimpawu zogcino | Ngenxa yokuchaneka okuphezulu kunye nemfuno ye-centrifugal air compressor, i-injini yomphunga kunye ne-expander, ukugcinwa kotshintshiselwano lobushushu kwi-fraction tower kufuneka kuxhotyiswe ngabasebenzi abaqeqeshiweyo nabanamava. | Ukugcinwa komatshini we-Gufeng, ipompo yokucoca kunye nevalve elawulwa yiprogram yonke isondlo sesiqhelo, esinokugqitywa ngabasebenzi abaqhelekileyo bokulondoloza. |

| Ubunjineli boluntu kunye neempawu zofakelo | Iyunithi intsonkothile, igubungela indawo enkulu, idinga iworkshop ekhethekileyo kunye nenqaba, idinga isiseko sokukhenkceza, kwaye iindleko zokwakha ziphezulu.Iqela lokufakela elinamava kufakelo lokwahlula umoya liyafuneka, kunye nomjikelo wofakelo omde, ubunzima obuphezulu (ifractionator) kunye neendleko eziphezulu zokufakela. | Iyunithi ineenzuzo zesimo esincinci, indawo yomgangatho ophantsi, ukufakwa okuqhelekileyo, umjikelo omfutshane wofakelo kunye neendleko eziphantsi. |

| Ukhuseleko lwenkqubo oluzenzekelayo | Kukho iiyunithi ezininzi, ngakumbi xa usebenzisa i-turbo expander ngesantya esiphezulu, kulula ukuchaphazela ukusebenza okuqhelekileyo kwezixhobo ngenxa yokungaphumeleli.Kwangaxeshanye, abasebenzi abanezakhono kufuneka bawunyamekele.Ukusebenza ukusuka kwiqondo lokushisa eliphantsi kakhulu ukuya kuxinzelelo oluphezulu kunomngcipheko wokuqhuma kunye neemeko ezininzi. | Emva kokuba umatshini uqalisiwe, unokuqhutywa ngokuzenzekelayo ngolawulo lwenkqubo.Ngenxa yokuba isebenza phantsi kobushushu obuqhelekileyo kunye noxinzelelo oluphantsi, akukho zinto zingakhuselekanga.Akukho ngozi kunye nomzekelo wokuqhuma. |

| Ukulungelelaniswa kobunyulu | Ukulungiswa kokucoceka okungahambi kakuhle kunye neendleko eziphezulu zokuvelisa i-oxygen | Ukulungelelaniswa kococeko olufanelekileyo kunye neendleko eziphantsi zokuvelisa i-oxygen |

| Iindleko zokuvelisa ioksijini | Ukusetyenziswa kwamandla: -1.25kwh/m³ | Ukusetyenziswa kwamandla: Ngaphantsi kwe-0.35kwh/m³ |

| Utyalo-mali lulonke | Utyalo-mali oluphezulu | Utyalo-mali oluphantsi |